Research On Safety Issues And Prevention Strategies Of Lighting Equipment In Stage Performances

With the continuous development of stage art, the importance of lighting equipment in performances has become increasingly prominent. Lighting can not only provide the audience with a clear visual experience, but also create a rich stage atmosphere through different colors, intensities and changes, and enhance the artistic appeal of the performance. However, there are also many safety hazards in the use of stage lighting equipment, such as electrical fires, equipment falling, and electric shocks. Therefore, it is of great practical significance to study the safety issues of stage lighting equipment and propose prevention strategies.

- I.The importance of stage lighting equipment

- II.Safety issues of stage lighting equipment

- 1.Electrical Fire

- 2.Equipment falling

- 3.Electric shock

- 4.Other safety issues

- III.Prevention strategies for stage lighting equipment safety issues

- 1.Prevention strategies for electrical fires

- 2.Equipment Fall Prevention Strategies

- 3.Prevention strategies for electric shock

- 4.Prevention strategies for other security issues

I.The importance of stage lighting equipment

Stage lighting equipment plays a vital role in stage performance art. It is not just a simple lighting tool, but also a powerful assistant in shaping the image of actors, guiding the audience's sight, and creating the stage atmosphere. Stage lighting can ensure that the audience can clearly see the details of the actors' performances and scenery, so that every movement and every expression can be seen. At the same time, the light can also be like an invisible baton, through clever rotation and transformation, to guide the audience's sight to move with the development of the plot [1]. In shaping the image of actors, lighting is even more indispensable. It can adjust the intensity, range and color to perfectly match the actors' movements and performance progress, making the character image more vivid and three-dimensional. In addition, lighting can also create different stage atmospheres according to the needs of the plot. Whether it is warm and romantic or tense and exciting, it can be achieved through the clever use of lighting, adding endless charm and appeal to stage performances.

II.Safety issues of stage lighting equipment

1.Electrical Fire

Although stage lighting equipment adds color to performances, the risk of electrical fires cannot be ignored. Long-term use can easily cause circuit aging and power socket damage, which can become a fire hazard. If the power of the lighting equipment exceeds the limit, or high-power equipment is densely connected to the same circuit, circuit overload is inevitable, and the risk of fire increases sharply. In addition, the location of the lamps must be carefully installed. If they are close to flammable bases or combustibles such as curtains, or the distance between lamps is too small and there is a lack of insulation measures, high-temperature lamps can easily become ignition sources and cause fires. Therefore, the use and management of stage lighting equipment must strictly comply with safety regulations.

2.Equipment falling

The risk of stage lighting equipment falling should be taken seriously. During the installation process, if the installer does not follow the equipment manual or uses inappropriate tools, it is very easy to cause the equipment to be installed unstable, burying the risk of falling. At the same time, after long-term use of the equipment, the parts will gradually loosen or even break due to wear and aging, which greatly increases the possibility of equipment falling. Therefore, ensuring the correct installation and regular inspection and maintenance of stage lighting equipment is a key measure to prevent falling accidents and ensure performance safety.

3.Electric shock

If stage lighting equipment has problems such as damaged wires, loose joints or poor insulation, it is very easy to cause leakage of equipment, posing a threat of electric shock to operators. In addition, when untrained and unauthorized personnel touch these equipment without authorization, or blindly operate without regard to operating specifications, the risk of electric shock accidents also increases. Therefore, ensuring the electrical safety of stage lighting equipment and strengthening professional training and safety awareness education for operators are important measures to prevent electric shock accidents and ensure personnel safety.

4.Other safety issues

In addition to the above safety issues, other safety issues may also occur in stage lighting equipment. For example, during the performance, due to abnormal control signals, unstable systems, uncontrolled performance lamps, or power system tripping, dimming cabinets not outputting and other problems, all lamps may go out. Failure is also one of the common safety issues. The scene fails seriously due to operational errors or system failures, or due to untimely maintenance and replacement of light bulbs and consumable parts, failure of certain parts, failure of the control system, etc., resulting in the practice that the scene effects and performance effects do not meet the design requirements. For example, the computer light is not firmly grounded, or there is no grounding wire, or the grounding resistance is unqualified, resulting in the breakdown of the lamp control components. Failure is also a common safety problem, mainly including control system failures leading to system failures such as dimming cabinets and lamps, and control signal out of control leading to the inability of digital lamps to operate normally. For example, the lighting console suddenly crashes, the system fails due to lack of hot redundancy; the network transmission signal is interrupted, resulting in some lamps not working according to the program, causing some system failures.

III.Prevention strategies for stage lighting equipment safety issues

1.Prevention strategies for electrical fires

A.Check the equipment regularly

Stage lighting and sound equipment should be checked regularly and kept in good working condition. Clean the equipment regularly and check whether the wires and power sockets are damaged or aging. Also, check whether the batteries and bulbs of the lighting equipment are working properly.

B.Correctly install lighting and decorative lamps

When installing lighting and decorative lamps, safety regulations must be strictly followed to ensure safety. A distance of at least 50 cm should be maintained between the lamp and combustibles, and the height of the lamp from the ground should not be less than 2 meters. If the height of the lamp is insufficient, protective facilities must be installed, and combustibles should not be stacked under the bulb. The protective cover of the lamp must be kept intact, and it is strictly forbidden to use paper, cloth or other combustibles to cover it to prevent fire.

For lamps on combustible ceilings, whether concealed or exposed, the power should not be too large, and incandescent lamps or fluorescent lamps should be preferred. Concealed lamps and their heating accessories should have good heat dissipation conditions around them to ensure safe operation. The wires of stage concealed colored lights, dance floor footlights, and lamps in combustible ceilings should be laid in steel pipes or flame-retardant hard plastic sleeves to improve fire resistance. The wires near the lamp tubes should be covered with heat-resistant insulating sheaths, and the wires of the hanging colored lights should be protected by rubber rings when passing through the keel.

In addition, when selecting ballasts, low-temperature ballasts with reliable quality should be preferred, and ballasts with high temperature rise should not be directly fixed on objects such as combustible large ceilings. The capacitance and capacity of the ballast must be consistent with the lamp tube to ensure the normal operation of the lamp.

When installing lamps in Class 0 and Class 10 explosion-hazardous places (Class 0 refers to explosive gas environments, and Class 10 refers to explosive dust environments), if open-type lamps are used to make wall-mounted niches, their inspection doors should be opened to the outside of the wall and ensure good ventilation. The side that illuminates the room should be tightly sealed with double-layer glass, and the horizontal distance between the lamp and the door and window frame should be no less than 3 meters, and the horizontal distance from the exhaust vent should be no less than 5 meters to ensure safety.

C.Reasonable control of electrical lighting

The lighting current should have its own branch circuit, and should not be connected after the main power switch. Each branch circuit should be equipped with short-circuit protection facilities. In order to avoid accidents caused by overload heating, some important places and places where flammable and explosive items are concentrated must also be equipped with overload protection devices. Non-explosion-proof lighting distribution boxes and control switches are strictly prohibited from being used in Class 0 and Class 10 explosion-hazardous places.

D.Strictly control lighting voltage and load

The lighting voltage is generally 220 volts. The power supply voltage of portable lighting fixtures should not exceed 36 volts. It should not exceed 12 volts when operating in humid areas, and the use of autotransformers is prohibited. The number of lamps in a branch circuit should not exceed 20. The civil lighting current should be less than 15 amps, and the industrial lighting current should be less than 20 amps. The wire specifications are determined by the load (each socket is measured at 2-3 amps). Emergency lighting fixtures should be installed in places prone to accidents, main entrances and exits of buildings, important workplaces, etc., and marked with obvious color markings so that they can be activated in a timely and convenient manner when an accident occurs.

2.Equipment Fall Prevention Strategies

In order to prevent stage lighting equipment from falling, the installation process is crucial. Installers must strictly follow the equipment manual and use professional tools for precise installation to ensure that the equipment is stable and reliable. At the same time, the daily care and maintenance of the equipment should not be ignored. Stage lighting equipment should be regularly inspected to promptly discover and properly handle potential problems such as wear and aging of equipment components. By strengthening maintenance, equipment can be effectively prevented from falling due to loose or broken components, ensuring the safety and smoothness of the performance.

3.Prevention strategies for electric shock

In order to prevent the risk of electric shock, the insulation performance of stage lighting equipment is crucial. Key parts such as wires and connectors should be checked regularly to ensure that the equipment is well insulated and effectively prevent leakage accidents. At the same time, strengthening personnel training and management is also a key link. All relevant personnel must receive safety training, enhance safety awareness, learn to use equipment correctly and strictly abide by operating specifications. Untrained and unauthorized personnel are strictly prohibited from contacting lighting and sound equipment without authorization to ensure personnel safety and ensure the smooth progress of the performance.

4.Prevention strategies for other security issues

In order to reduce the occurrence of other safety problems such as failure and uncontrolled lighting equipment and systems, a regular system detection and maintenance mechanism should be established, including stability testing of control signals, updating of system software, etc., to ensure that the system is in the best operating state. At the same time, dual or multi-way power supply and hot backup control system can be used. When the main system fails, the backup system can take over immediately to avoid performance interruption. Use high-quality signal lines and shielding measures to reduce the impact of electromagnetic interference on control signals and ensure the accuracy and stability of signal transmission. In terms of power system protection, monitoring equipment needs to be installed to monitor voltage fluctuations, frequency changes, etc. in real time, and take timely measures to avoid damage to lighting equipment. Regularly conduct safety inspections on power lines, distribution boxes, etc. to ensure good grounding and reduce safety hazards. In addition, a detailed equipment maintenance plan needs to be formulated, including regular replacement of wearing parts and preventive inspection and maintenance of key components to ensure that the equipment is always in good operating condition.

IP66 672pcsx0.5w rgb 112pcsx3w cool white led strobe bar light with seethonic power plug, electric frost & clamps

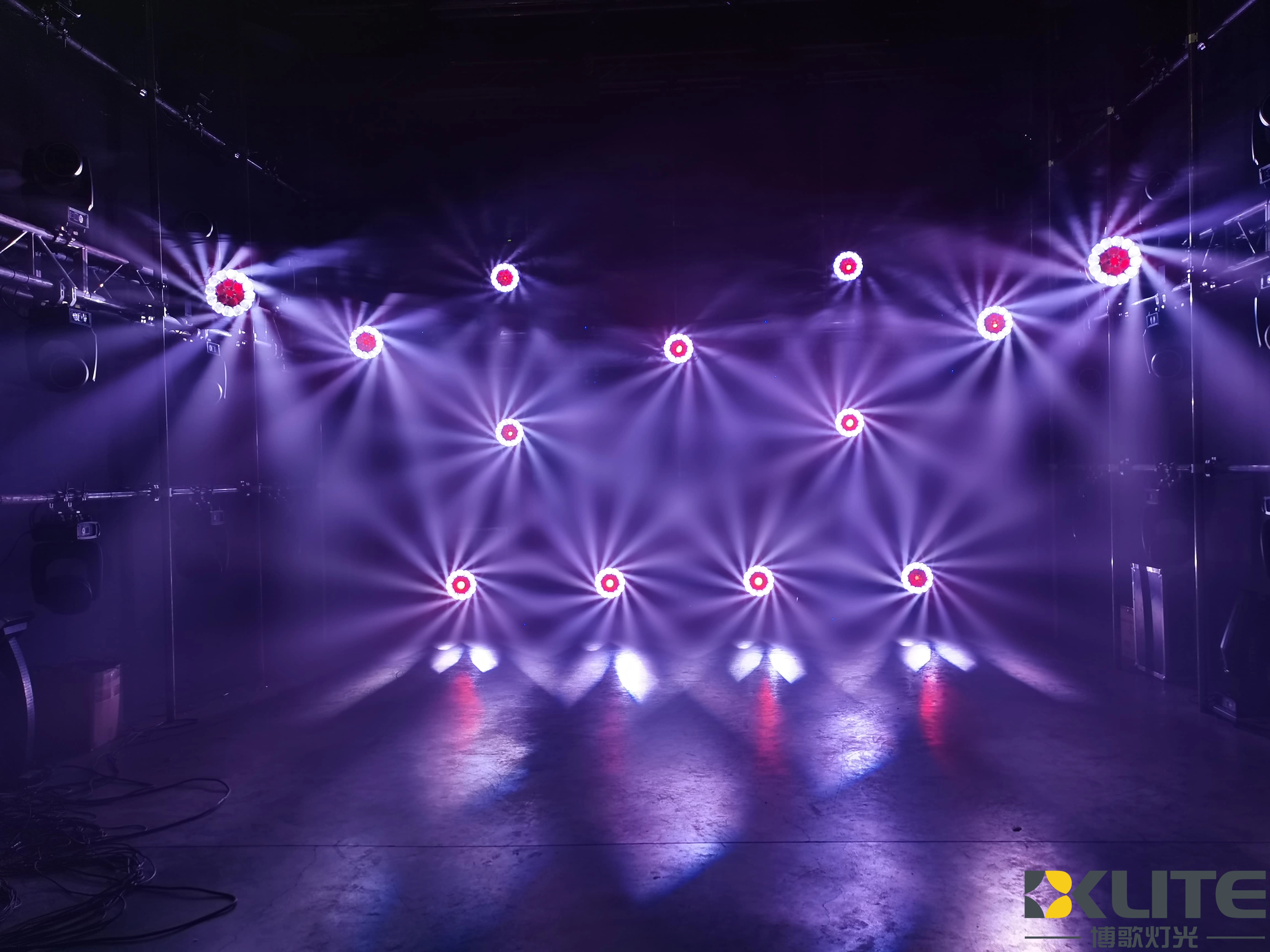

BKlite Zoom Bee Eye K15 19x40w rgbw 4in1 Led Beam Wash Moving Head Light with LED Ring

Bee eye k10 ZOOM 19x15w rgbw 4in1 led beam wash moving head light

Bee Eye K10 LED Moving Head Light – 19×15W RGBW Zoom Fixture for Professional Stage Lighting

The All-in-One Solution for Modern Stage Lighting - IP20 Bee Eye 19×40W RGBW LED Moving Head Light

What Makes LED Lights So Special?

FAQs

What's the shipping way, shipping time?

The ways of shipping—you can choose which is suitable for you. (1). By Sea, 30-60 days; apply for bulk quantity.

(2). By Air, 5-7 days; apply for bulk quantity.

(3). By Express, 3-5 days; apply for small quantity and urgent order.

If the products broken during the warranty, what should i do?

If there is a problem with the products, you describe it and send pictures or videos to us to analyze, and then we will guide you on how to fix it and provide spare parts for free if needed.

What is your delivery time?

For stock products, we will deliver to you within 3 days.

What's the payment terms?

T/T, Western Union.

When will you ship the product after I send the money?

It depends the order.Small order will take 3-5 days.

What's your certificates?

ROHS and CE certificates passed.

IP65 Waterproof Bee Eye Zoom 19x40W RGBW 4IN1 LED Beam Wash Moving Head Light with LED Ring

BKlite waterproof bee eye moving head light—your reliable choice from top waterproof moving head light manufacturers and suppliers. Ideal for outdoor stage, live event, music festival, this energy-saving fixture ensures powerful, precise illumination for any venue. It delivers powerful, reliable lighting performance in any weather.

IP65 Waterproof ZOOM Bee Eye 37x40W RGBW 4in1 LED Moving Head Light

As a leading stage lighting equipment supplier with more than 15 years of industry know-how, BKlite brings you the IP65 ZOOM Bee Eye 37*40W RGBW 4in1 LED Moving Head Light (K25 Bee Eye) delivers vibrant, weatherproof lighting with powerful zoom and smooth movement. Ideal for dynamic stage effects, the K25 moving head light ensures stunning RGBW color mixing and reliable outdoor performance.

Bee Eye Zoom 37x40W RGBW 4in1 LED Beam Wash Moving Head Light

IP20 Bee Eye Zoom 19x40W RGBW 4IN1 LED Beam Wash Moving Head Light with LED Ring

As one of the leading stage lighting equipment suppliers with 15+ years of experience, BKlite launched a new Bee Eye K15 19x40 LED wash light BK-BY1940Z. .

Designed with a simple and sleek appearance, the WASH moving head light is compact, lightweight, and highly portable.

With multiple color effect macros and dynamic effect macros.

Our wash light can be used for versatile lighting options with amazing effect.

It is very good for your lighting projects.

Powerful and shoots very far distances.

Contact us

Let's discuss how we can work together to achieve your business goals. Contact us today to get started.

Address

No. 30, North Hongmian Avenue, Huadu District, GuangZhou, China.

Copyright © 2025 BKLITE All Rights Reserved.